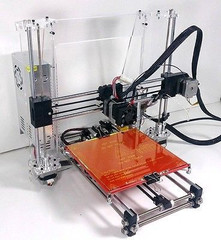

So you have seen my woes. I learned ALOT about 3d printers during the build and trials and tribulations. But once I had it pseudo working the first thing I wanted to print…. UPGRADES!!!

“#$%^& YES!!!! Print your own upgrades!” I yelled at the printer!

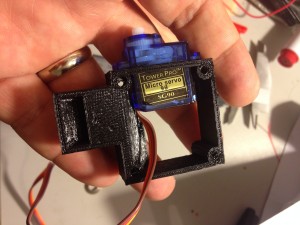

I printed a new fan shroud that has a vent to help cool the plastic as well as a slot for a 9 gram servo motor.. Why you may ask? Well, its for the auto bed level!

This seemed like the holy grail at the time, it is still pretty cool, but I have found it does put some extra wear and tear on your z-axis nuts and rods.

I basically build it based of this guys videos

This is still a pretty cool feature. I have even used the time it takes to auto level to change my heat bed temps by using some custom “start gcode” in CURA

1G21 ;metric values

2G90 ;absolute positioning

3M82 ;set extruder to absolute mode

4M107 ;start with the fan off

5G28 ;move Z to min endstops

6G29

In short, my CURA profile has the heat bed set to heat up to 55 degrees. I personally like it at 65. So once that initial 55 is hit for the heatbed and the hotend it starts this custom G-Code. That first line says “set the head bed temp to 65” then it moves on to some of the other settings. The G28 and G29 are related to the auto bed leveling. So while its probing various points, the bed is heating up to my desired temp.

Its funny I have this little guy printed in black abs, black pla, red pla and gray pla in my house.

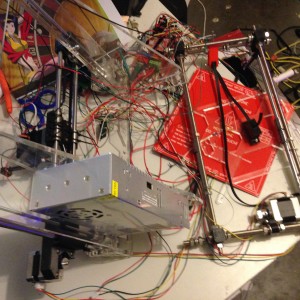

This hurt. For over a week I had my printer ripped back apart.

Comments